Here is a low cost method for experimenting with printed weather proof QR codes to promote a local product or service on a website.

The following labels, stickers and banners can be produced at minimal cost before committing to a professional print run.

By gathering the materials at low cost (or even free if you beg or borrow) it is possible to raise awareness of and funnel people to a website landing page.

Generate Your Codes

To actually generate the Quick read (QR) barcodes, search online for a high quality QR code generator website and punch in your webpage URL.

You can read about how I generated these codes for local fast food businesses. In my example, they have been produced with monetisation and website traffic building in mind.

The QR codes are designed with references to online payment systems, and because I needed to be able to track how many people are scanning the codes with their mobile device QR reader I set up Google Analytics tracking using the GA URL builders.

It is strongly recommended you do this. My logic in advertising via a print medium is to capture more potential users of the site who may not be aware of its existence.

Weather Proof the Paper

I once worked in a factory that made warehouse labeling systems, where we manufactured laminated sticky banners bearing stock control data.

I was able to save large off-cuts for personal projects. Several years later these same manufacturing techniques are serving my own promo experiments with QR codes.

The laminated surface protects the QR code from becoming damaged. 🌦️☔

The necessary supplies are things like laminating film and double sided self adhesive which, in the event of the QR barcode becoming defaced, will still work.

Read about QR error correction here.

What Materials to Create QR Codes?

In the image below the left roll is double sided self adhesive and the right roll is single sided clear laminating film.

Adhesive materials for creating waterproof QR stickers

You can purchase the required items online at low cost.

If it’s a small niche or test market you’re designing QR barcodes for, an inkjet printer set to high quality with decent photo paper is adequate for printing.

Just be sure to laminate if they’re going outdoors or on cold windows. ☔

Design Layout Tips for Printed QR Campaigns

Gimp has similar capabilities to Photoshop and is free. Paint.net is also free and has similar functionality to Photoshop.

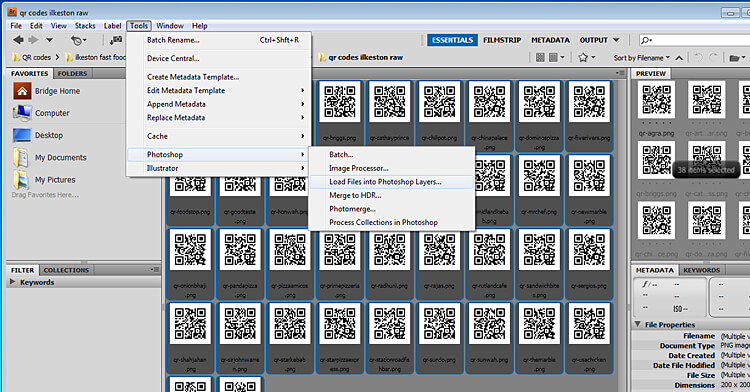

Assuming you have Adobe Photoshop, do yourself a favour and download Adobe Bridge too. 🙏

Bridge allows you to import multiple images as multiple layers to a single Photoshop document. 👍

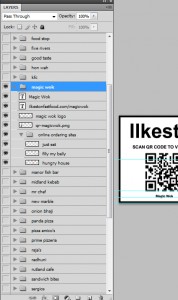

As you can see from the screenshot below, I selected all my QR codes (first copied to a single folder) and clicked “Tools”, scrolled down to “Photoshop” and selected “Load files in Photoshop Layers”.

This helps me to start grouping and labelling each QR code in Photoshop, with all the other artwork built around it. 🤓

Remember to:

- Name each group and layer

- Organise ALL your layers into groups and sub groups

Each Photoshop layer group contains the appropriate QR code, text, business logo and online ordering logo. 🖥️🖱️🔍

It was quick to create some simple QR codes, but I spent a bit longer on mine since I was experimenting with other information that can be built in to the code besides the usual URL to a website. 🔗🪪

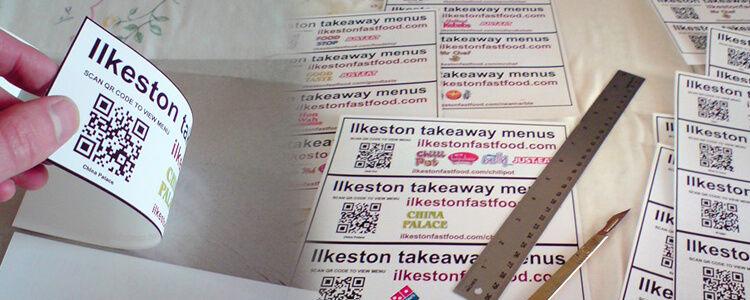

Producing the Printed Materials

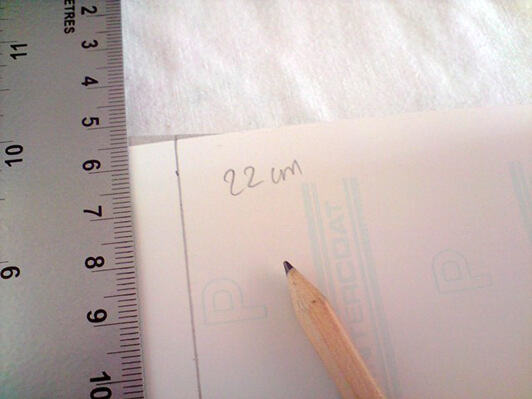

A ruler and sharp knife will be needed. A small guillotine or trimmer is an alternative.

Mark roughly where the cut needs to be made. Measure enough to leave enough a margin for error. The photo below is a rough indicator of what you must do.

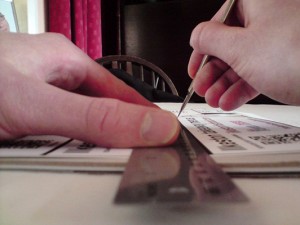

Apply even and smooth pressure to the back of the label on the double-sided adhesive

Smoothing bubbles by applying pressure with a flat object is always necessary.

Sticky Back Adhesive for Windows

Do you need your stickers to go onto glass facing outwards? Double sided clear adhesive comes with a wax paper which is simply peeled back and discarded, same as the previously shown laminating film.

People on the street can see and scan the QR code through the window glass.

Apply the double sided adhesive repeating the steps shown previously for the laminating film. Be careful where you place it because the adhesive is high tack.

Ensure the surface is not dirty before choosing where to stick your QR code label.

The waxy paper is peeled away to reveal the sticky clear adhesive. This is pressed against the inside of the shop window.

QR Code Production Tips

- Get familiar with Abobe Photoshop, or similar software

- Get a good craft knife and sharp blades

- Obtain adhesive or laminating film

- Measure QR scans with Google Analtyitcs, Hubspot or similar web analytics software

More Stuff on Cheap, Practical Use of QR Codes in Small Business

📱 In the Pandemic, QR Codes are Finally Proving Worthy in the West

📱 QR Codes Could Get the Chance They Deserve Thanks to iOS 11

🍴 Fast Food Restaurant Owner? Market Your Menu with QR Codes

Add Your Thoughts